1. Conservation interventions

The conservation proposals for each wooden part are divided into salvage interventions, systematic conservation interventions and preventive conservation interventions.

The basic principle for the organization of all interventions is the use of materials and methods that are compatible with the original elements in order to integrate them into the historical structure. In addition, the proposed interventions will be carried out in accordance with the methodology and application specifications of the materials used and with particular care to avoid further damage.

All parts originating from controlled dismantling are assessed according to the extent and quality of the values and information they contain. Those parts that prove to be unusable for the intended goals of the overall project as well as for possible future plans to preserve, utilise and promote the surviving elements of the ship, will not be reused.

2. General principles of conservation – restoration procedures

The methods, materials and extent of conservation and restoration measures for a declared protected structure are primarily determined by four factors:

- A good understanding and diagnosis of the structural system

- The nature and extent of the deterioration mechanisms

- The modern expertise available

- The existence and scope/content of protection and intervention regulations

The intervention and rehabilitation process follows three phases in particular, which should not be omitted and whose sequence should be strictly adhered to. These phases are:

- The examination of the pathology

- Documentation of the state of preservation

- Interventional or preventive conservation

The basic principles of conservation and restoration studies are to achieve as much compatibility and reversibility as possible. After the structural analysis and the evaluation of the pathology, the conservation and restoration proposals are elaborated. These may be proposals for immediate salvage measures or final proposals.

3. Interventions for the conservation – restoration of historic wooden structures

Objectives and selection

In order to obtain as much information as possible about the protected wooden structures, we need to prioritise their characteristics according to their importance, so that their conservation can be based on the value of these characteristics. These values are mainly determined by a greater emphasis on shape, dimensions and surface details (carvings, signs of use, and other traces). Colour (the permissible colours for preserved wood are limited) and texture are classified as values of medium importance, the least important being the composition of the wood, its weight and the preservation of the object’s previous use. However, the main value of wood as a material for the construction or decoration of protected structures is its original appearance, which should be preserved as much as possible.

The conservation and restoration of wooden structures is a complex and specialised process due to the complex technology of their construction using multiple materials and techniques. Therefore, the successful conservation and restoration of wooden structures requires the parallel application of different techniques, methods, and materials. Therefore, proposals for conservation and restoration interventions should be elaborated in accordance with the characteristic deterioration described in the state of conservation assessment, both in terms of material (wood, metal, etc.) and of the entire structural system. The final intervention scheme will be consistent with the overall pathology of the structure and the results should be evaluated according to technical, aesthetic, and economic criteria.

Although much research has been carried out to find the most suitable methods of wood conservation, the final choice of methods and materials and the extent of their application will be made on a case-by-case basis and only after appropriate experimental applications on large quantities of corroded material samples in order to draw firm conclusions. Only in this way can the safest and most effective choice of the most suitable conservation methods be guaranteed.

The choice of application of each material and method of timber construction intervention is mainly determined by:

- the principle of the minimum intervention,

- the extent and difficulty of the application,

- the cost of the application and

- the availability of equipment and materials

The requirements that the materials to be used for the conservation of wooden structures are as follows:

- In particular, when used, they should alter the physical properties of the original material as little as possible.

- They should retain their physical and chemical properties as a material over time.

- They must be able to be removed from the object in the future without damaging it (reversible process)

Conservation work should also be guided by the ethical principles of the international charters for the protection of cultural heritage.

It must always be emphasized that, despite the specific guidelines contained therein, the final decision to intervene, regardless of the outcome, is left to the discretion of the individual researcher.

In general, a complete conservation intervention on a wooden structure comprises the following steps in order of priority.

- Salvage interventions

- Cleaning of the surface

- Removal of newer paint and other interventions

- Disinsectization measures – protection against biological infestation

- Measures to consolidate the wood

- Restoration of structural damage

- Aesthetic restoration

- Finishing

- Evaluation of conservation methods

4.Methodological and practical description of conservation – restoration procedures of historical timber structures

1. Salvage interventions

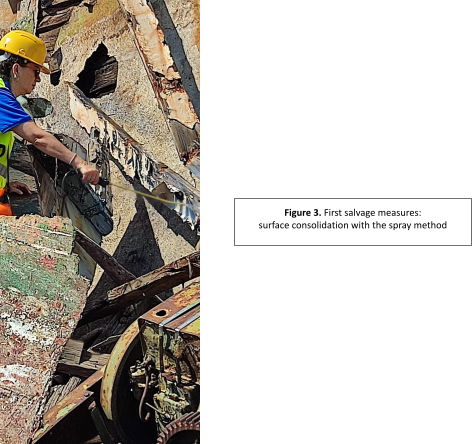

Salvage interventions are carried out to preserve the structure and appearance of the surface as well as the integrity of the material. Depending on the degree of surface deterioration of the timber sections, an initial consolidation was carried out to preserve the timber mass and the information it contains in the areas where it is exposed to severe corrosion. Repeated spraying of a 3 – 10% solution of Paraloid B72 in acetone, with progressively increasing levels of spray solution of 3%, 5%, 7% and 10% until the surface is saturated. In case of high ambient or material humidity, a corresponding spray application of Primal SF016 acrylic suspension, 5% – 10% w/w in deionised water was used.

2. Systematic conservation interventions

All systematic conservation measures are aimed at preserving and enhancing the wooden elements, respecting their historical and aesthetic heritage and based on the principle of minimum intervention.

2.1. Surface cleaning

The cleaning of the surface initially involves the removal of debris, superficial impurities and precedes the rest of the work. Removal is mainly carried out by brushing and rinsing with deionized water using a pressure-controlled pre-pressure sprayer. A controlled low- pressure water jetting may also be used for leaching.

2.2. Removal of newer paint and other interventions

The cleaning of wooden elements also includes the removal of corroded layers of paint and varnish. The corroded layers are removed down to the surface of the natural wood.

The cleaning of newer coats of oil-based paints and coatings of varnishes and other coating materials, is carried out using chemical and/or mechanical methods.

In chemical cleaning, a suitable solvent or corrosive is selected to corrode the newer paints and coatings without affecting the possible original colour or surface of the wood. The solution is applied or sprayed onto the surface and then the softened paint is removed mechanically using hand tools, such as trowels. Finally, the surface is cleaned with a selected solvent, usually white spirit.

Organic solvents, such as acetone or Vulpex, are also used as a neutral surfactant soap in a 5 – 10 % w/w solution in white spirit and rinsed with the same solvent, to simultaneously remove greasy deposits and corroded coatings, after cleaning attempts.

Localized deposits of all the above materials can first be soaked in the selected solvent and then removed by controlled rinsing, low-pressure water jets or mechanical hand tools.

Mechanical cleaning with prior heating with a heat gun instead of a solvent or corrosive is also a common method, followed by removal with suitable hand tools and rinsing with a selected solvent, usually white spirit.

2.3. Disinfestation interventions – protection against biological infestations

Control methods for wood-eating insects have a suppressive role in detecting an active infestation or act as an invasive and preventive measure to protect against a possible future infestation.

Control methods for wood-eating insects can be categorized according to the type of implementation and technology used. In this sense, a distinction is made between methods that are carried out using chemicals in liquid form, such as insecticides or wood preservatives. There are also methods in which fumigation is carried out using fumigants, that leave less residue on the object and are therefore considered less harmful to humans. In addition, control can be carried out using natural methods that utilize the effect of natural properties or environmental factors and leave no harmful residues on the object. Each method is considered successful if it removes the infestation from the wood and kills the insects at all stages of their life cycle.

2.4. Methods of applying liquid preservatives

The composition of wood preservatives consists of the biocidal substance or a combination of biocidal substances and water or a solvent mixture as a carrier. After application, the solvents volatilise quickly and the biocidal substances remain in the wood. The penetration of the preservative into the wood depends on the type of solvent contained in each case as well as the state of preservation and the extent of the individual infestation of the wood. As a rule, preservative formulations that use solvents as a medium have better permeability without causing the wood to swell, as is the case with water-soluble preservatives.

Liquid wood preservatives can be applied by various methods, which can be categorised into those that do not require pressure, such as brush application, methods that are applied under pressure and in vacuum conditions, and specific methods for treating a particular area.

The non-pressurized methods are mainly surface-based and sometimes effective up to a few millimeters below the surface, but without any deeper effect.

In the methods where the insecticide is applied to the surface of the object, the substance penetrates to a depth of a few millimeters without ensuring a penetrating effect throughout the mass of the object, and since a large amount of the insecticidal substance evaporates in a short time, due to the high volatility of the organic solvent, it is not suitable as a means of protection against future infestation.

Methods in which the objects are immersed for a short time in containers with preservative also do not have a great depth effect, so that these methods are used more as a preventive measure against infestation. Methods applied with pressure show the best performance in terms of penetration of the substances, as far as this is possible, based on the permeability allowed by the type of wood and the size of the object to be applied.

Objects with severe damage and rot absorb a larger amount of insecticide with this method. Conservators usually treat active insect infestations with diffusion methods by applying the insecticidal substance to the interior of the object using a syringe or other equipment. The substance penetrates better into the interior of the object than the surface and short dip method, as it is channelled to a greater depth through the exit holes of the insects and the cracks in the wood. However, it is not certain that the substance will penetrate the entire length of the tunnels, so insect larvae and eggs in active infestations are not certain to be completely neutralised.

Wooden objects of historical importance require special handling, using methods that are considered less intrusive and do not cause deterioration. The methods that best serve these purposes are those applied by diffusion and those that do not require the application of pressure.

The combination of user-friendliness and low costs is achieved by applying surface methods using liquid preservatives. The application of liquid preservatives is even better supported by immersion methods. These methods are associated with minimal costs, no special equipment is required, only tanks of an appropriate size for immersing larger surfaces, and the application time is short. The application of these methods is particularly suitable for controlling smaller infestations, because the wood does not penetrate deeply. As the number of applications increases, a higher percentage of the insecticide is concentrated in the objects, which ensures better effectiveness.

2.5. Treatment with fumigation methods

In the treatment of insects by fumigation, substances are used in the gas phase that have a biocidal effect under normal temperature and pressure conditions. These substances include gases, but also vaporised liquids and solids. Fumigants are used to eliminate active insect infestations on wooden objects and entire rooms. The effectiveness of the method depends on factors such as the type of fumigant, its concentration rate, and the duration of exposure to the object. The relative humidity and the moisture content of the object under ambient conditions are also important.

The smoke gases show a better, deeper and faster penetration into the wood as well as a more even diffusion compared to liquid preservatives. In addition, a large number of objects can be disinsected simultaneously and in a shorter time than is the case with liquid wood preservatives. However, fumigation methods theoretically offer no preventative protection against possible future infestation, as the vapors escape from the wood after application through the necessary ventilation. As a rule, they do not leave any residues. At the same time, some of the active substances used in the smoke grenades are highly toxic.

On the basis of toxicity and chemical activity, smoke gases can be categorised into highly reactive substances, that are very toxic to humans and the environment, and inert or less active substances, which pose no immediate health risk. Active smoke gases can sometimes remain in objects for a long time after application, where they can lead to permanent harmful changes in certain materials under ambient conditions with high relative humidity and high moisture content of the material. Inert smoke gases, require a longer exposure time to objects, but this can be minimized by increasing the temperature or pressure, or even by a combination of the two factors mentioned above.

For mobile objects, fumigation methods can be carried out in special bags, boxes or pressurised chambers, raising the question of the possibility of handling large objects. If rooms or buildings are fumigated, they must be sealed inside and out with airtight membranes.

For cultural heritage objects, the least harmful substances, such as inert or low-activity smoke gases, should always be used.

With fumigation, the insecticides act faster and penetrate the wood better and more evenly than with the methods mentioned above. The area in which the process is used must be sealed so that no gases can escape into the atmosphere. In addition, fumigation leaves little to no residue on the items after preservation. Most of the gases used destroy all growth stages of wood-eating insects. If gases with insufficient ovicidal effect are used, this is treated by prolonged exposure of the object to the active ingredient or by a combination of techniques. In addition to the effectiveness of fumigation, an advantage is that the method can also be used on larger and immobile objects conserved in situ.

The method of disinsection is considered effective if, in the case of active infestation, the extermination of the insects is achieved at all stages of development, i.e. the larvae and their eggs are killed in addition to the finished insects. Some methods have moderate results as they only kill the perfect insects or have an inhibitory effect on an active infestation. The insects therefore do not stop reproducing in the wood and their destructive activity continues over time. Other methods are limited to protecting against future infestation without having any significant effect on objects that are already infested.

2.6. Dealing with bulky – immovable objects

The treatment of larger art objects, such as parts of larger wooden objects and wooden structural elements, cannot be treated with some of the applications that preserve small wooden objects. If these items cannot be moved, they must be treated in situ, which further limits the possibilities of disinfestation methods.

Large wooden elements that can be transported can be taken to the laboratory and disinsected by methods using liquid insecticides. Depending on the size of the infestation, the insecticides can be applied superficially or immersed for best results, always depending on the size of the object. In the case of active infestations, however, the results of the above methods are not entirely satisfactory. Spraying, apart from the low penetrating ability, is considered unprofitable due to the high loss of material during application. Even with immersion, there is no guarantee that the active ingredient will penetrate to a sufficient depth, as the cross-sections of the objects are very thick.

The ability to move bulky wooden elements allows them to be transported to fumigation chambers, which can ensure the best results in active infestation, but is considered very costly.

2.7. Natural control methods

The activity of wood-eating insects is highly dependent on environmental factors such as ambient temperature, atmospheric pressure and air humidity. The consideration of these factors is the basis for the application of physical control methods. The aim is to stop the process of reproduction of the harmful organism and at the same time to eliminate the active infestation by changing the environmental conditions. The temperature of the living environment of wood-eating insects has a direct effect on their metabolism. Therefore, extreme temperatures can be fatal after a short time of exposure. Natural methods are also used to combat fungi, which are destroyed at high temperatures.

Compared to the methods mentioned above, natural control methods are better suited to the toxicological and ecological concerns of cultural artifacts made of wood. In contrast to liquid preservatives, the application of natural methods leaves no residue on the objects, and there are no problems with the compatibility of the preservatives with the material, and there is no possibility of causing small or large changes to the objects, as with fumigation methods.

In addition, disinsection using heating can lead to a partial denaturation of the wood proteins, which diversifies the food source of the wood-eating insects and thus prevents possible future infestation, but this cannot be considered a sufficient preventive method. In general, natural methods do not show satisfactory results as preventive conservation measures.

The most important natural methods are:

- Thermal methods

- Cooling methods

- Suppression by humidity modulation

- Suppression by pressure fluctuations

- Treatment with sound and electromagnetic waves

- Control of insects by biological methods

2.8 Heat treatment of timber according to ISPM15/FAO

One of the modern methods of combating phytopathogenic and wood-eating organisms is the thermal treatment of timber. The application of this practice is defined by the World Organisation for Agriculture and Food (FAO) in application of the international standard ISPM 15.

During heat treatment in accordance with ISPM 15/FAO, the temperature inside the wood is raised to 56 °C for at least 30 minutes. According to this standard, this practically eliminates all living pathogenic organisms that could live in the wood. However, using this method does not completely guarantee that future infestation or re-infestation of the wood will be prevented.

A sufficient number of heat treatment chambers for the application of the method are also installed in Greece.

2.9. Preventive measures against wood-eating insects

Preventing infestation with wood-eating insects has the advantage that it is possible to react immediately with simple means, which reduces the time and costs required for control, whereby small and large objects are affected.

Infestations can be systematically controlled through preventative management programmes, using appropriate storage and exposure conditions. Creating an ideal microclimate prevents the spread of wood-eating insect populations by setting the relative humidity and temperature to levels lower than those that favor their growth. These conditions should be monitored and recorded using data loggers.

The implementation of Integrated Pest Management (IPM) comprises the following steps:

- Assessment of the type and extent of infestation

- Prevention of spread through control of input materials

- Implementation of a procedure to eliminate an active infestation

- Evaluation of the infestation control and the control mechanism

- Implementation of preventive protective measures against future infestations

In the initial phase, preventive conservation is based on avoiding or reducing the causes of insect infestation in the storage rooms of wooden objects. In practise, this is achieved by increasing the level of hygiene and regulating the environmental parameters in the storage rooms. Checking for active infestation is also a practice that should be carried out regularly, roughly following the development cycle of the insects. An inspection of the entire building should be carried out approximately every six months. Signs of insect infestation include live or dead insects in various stages of development, feces, droppings and other features.

The detection of an infestation of wood-eating insects triggers the next stage of prevention, which is to prevent its spread to other objects in the area by isolating it. At the same time, the premises surrounding the infested area should be inspected to assess the extent of the problem and identify the source of the spread.

3. Wood consolidation measures

Consolidation processes mainly involve the introduction of preservatives into the wood mass, which more or less protect the wood from the destructive effects of decay factors, maintain it in its current state and significantly improve its physical and mechanical properties in order to extend its life and/or improve its performance as a material.

Consolidation materials must fulfill certain requirements. These are that they must have good bonding and cohesive properties, achieve good penetration, be durable and stable and not change the appearance of the object. The consolidation materials themselves must have sufficient strength, elasticity and hardness, be non-deformable, retain their mechanical strength and not discolour over time. It is also important that they are reversible, non-toxic, cheap and easy to obtain. Finally, the properties of an ideal consolidant should be similar to those of the wood structure.

Similarly, the ideal solvents should easily dissolve the fixatives at room temperature and at different concentrations, should not cause moisture deprivation when used on dry wood, but should also have a relatively high boiling point to achieve better penetration of the fixative before evaporation. Finally, the ideal solvent should not affect the structure of the wood, should not be toxic and its properties should allow it to be used safely.

Although surface tension determines the extent to which the solution penetrates a solid material with pores, there are other factors that determine the degree of penetration. The two most important are viscosity and porosity. As far as solvents are concerned, their polarity, boiling point and viscosity are important factors that influence their penetration properties.

Viscosity is directly dependent on temperature, i.e. it decreases with increasing temperature. The porosity is mainly characterised by open porosity, i.e. the percentage of pores that are in contact with the surface and must be as large as possible so that the solidifying solution can move. In addition, polar solvents such as water, acetone and ethanol, unlike non-polar solvents such as toluene, provide excellent strength and allow better penetration of the solutions. Non-polar solvents do not provide high strength and their mobility is reduced due to absorption by the cell walls. It is also reported that the bonding agents in non-polar solvents have very poor adhesive properties compared to the same adhesives in polar or a mixture of polar and non-polar solvents. Finally, solvents with a low boiling point should be preferred as they reduce vapors.

3.1. Consolidation by spreading

With regard to the method of applying the consolidating solution, it should be noted that application with a brush only achieves hardening in the surface layers. In order to achieve slightly better results with this method, low-concentration solutions are used, which also do not produce a glossy surface so easily.

3.2. Consolidation by immersion

Better penetration can be achieved by immersion in a consolidation solution or by spraying in a closed circuit. The process of complete vacuum impregnation should also provide ideal results.

During immersion, the material should be applied by repeated immersion in solutions of different densities, starting with the thinner solutions and gradually moving to the denser ones. It is recommended to apply as many times as necessary until the surface is saturated (polished), gradually increasing the concentration of the fixative in the solvent.

It is obvious that the effectiveness of immersion is comparatively limited if controlled application conditions cannot be achieved and no immersion consolidation is carried out. At the same time, the success of immersion requires thorough cleaning and removal of all types of deposits, and the period between July and August is recommended as the most suitable time to carry out the work.

There are many classes of consolidating solutions used in dry wood preservation, but the most commonly used are:

- Thermoplastic resins (e.g. AYAA, AYAC, AYAF, AYAT)

- Polyvinyl ketones (PVAs, e.g. Mowilith 50)

- Polyvinyl butyral (e.g. Butvar B98)

- Polyvinyl ketone suspensions (e.g. CM Bond M2)

- Acrylic resins (e.g. Paraloid B72, Acryloid B72)

- Polymethacrylic suspensions (e.g. Primal, Bedacryl)

- Polymethacrylic adhesives (Polymethacrylates, e.g. Elvacite 20/3)

- Polyvinyl alcohols (Polyvinyl alcohols, e.g. Mowiol 3 – 83)

- Epoxy resins (e.g. Araldite)

- Natural resins (e.g. rosin)

- Organic and inorganic waxes

Not all of the above-mentioned consolidants have been studied in wood research. Those that have mainly been studied and used are polyvinyl polymers (PVAs and Butvar), acrylic resins (Paraloid B-72), polymethacrylic suspensions (Primal), epoxy resins and natural resins in combination with waxes.

For polyvinyl polymers (PVAs), the strength they impart is reported to be unsatisfactory (compared to Paraloid B72 acrylic resins and polyvinyl butyral, Butvar).

PVA emulsions have been reported to give the best results as consolidants and not as adhesives. For Mowilith 50 in particular, it is reported that its application on organic materials causes an unacceptable change in their colour. For the above reasons, Mowilith is often used as a fixative in the pre-fixation of organic materials, as it retains the elastic properties of the material but is subsequently removed.

Polyvinyl Butyral is also not evenly distributed in the wood and its strength is low. In hardness tests, they did not produce satisfactory results, although they were better than polyvinyl ketones. It is claimed that Butvar has the best strength, followed by acrylic resins, with polyvinyl ketones coming last. In terms of durability, Butvar B98 is said to give the best results, followed by Acryloid B72 and finally Butvar B90.

Acrylic resins and methacrylic suspensions with Paraloid B72 (Acryloid B-72) as the most important “representative” are said not to distribute evenly in the wood and do not have a high resistance to hardness tests, although they are generally better in comparison to the others (polyvinyl acetates, polyvinyl butyrals). However, it is claimed that the fixative that fulfils all the above requirements for fixatives (compared to the others listed) is Paraloid B72. For the application, it is recommended to immerse Paraloid B72 in an acetone solution of 3-8 % w/w.

It is obvious that it is not possible to achieve ideal laboratory conditions for impregnation by simple immersion, and therefore the effectiveness of impregnation by this method is limited compared to immersion under vacuum. Nevertheless, it is believed that the use of Paraloid B72 solution under non-laboratory conditions can achieve most of the percentage increase in surface strength seen in the laboratory compared to other consolidants.

Epoxy resins are suitable for bonding almost all materials. They solidify without shrinkage and without producing gaseous or liquid by-products. Epoxy resin weld seams are resistant to chemical attack and provide excellent sealing and insulation against moisture.

Among the natural resins, the excellent behaviour of the wax-colophony mixture (1/1) is particularly noteworthy. In terms of penetration, wax with rosin dissolved in trichloroethylene at room temperature has given very satisfactory results, but the solvent is toxic to health, especially in uncontrolled immersion applications.

3.3 Polyethylene glycol immersion

For the application of consolidation treatments of wet and mainly water-saturated wood, immersion in aqueous solutions of polyethylene glycol (PEG) using the two-stage methodology has been successfully reported. A low molecular weight polyethylene glycol (PEG 400) is used in the first stage and a high molecular weight polyethylene glycol (PEG 4000) is used in the second stage. The final PEG concentrations in aqueous solutions are calculated with the help of the PEGcon software used by the Canadian Conservation Institute (CCI). Based on the proposed concentrations for each PEG molecular weight and the state of preservation of the objects, the individual steps of the impregnations are organized, which are carried out in sealed plastic tanks under ambient conditions.

Excess solidified PEG is then removed from the surface of the objects by mechanical or chemical cleaning using ethyl alcohol as a solvent.

Reversibility of consolidants

As is generally the case, the consolidation material used should be reversible. Reversibility is particularly important for materials that are applied in situ in an uncontrolled manner, as the application conditions are almost always less than ideal. It should be noted that the term should not refer to the material, but to the process as a whole. Specifically for the consolidation process, it should be noted that even if a consolidant is easily soluble, it is particularly difficult to remove completely, as repeated applications of solvents can damage the surface of the wooden object.

It is reported that acrylic polymers are easier to remove than Polyvinyl butyral. It is also pointed out that toluene as a solvent causes reversibility problems. In reversibility studies with solutions of Paraloid B72, polyvinyl butyral (Mowital B30H and B60H) and a mixture of paraffin and colphone (1:1), the wax-colphone mixture showed the best reversibility with twice the speed of Paraloid B72 and ten times the speed of polyvinyl butyral.

4. Structural damage restoration

When applying structural damage restoration interventions, the following steps are followed in order of priority for most wooden structures in need of restoration.

- Removal and clearing of contaminated and damaged areas

- Cleaning of the remaining damaged areas of the wood

- Prevention of future biological infestation of all undamaged or contaminated areas of wood

- Replacing the damaged and removed area of the timber element with a new section of natural timber of the same species or treated timber, suitably shaped so that it can be connected to the existing one to safely support loads

- Replacing the removed part with another material such as steel or resins mixed with cellulose molecules

- Adding internal steel or synthetic reinforcement to connect the existing timber elements to the new ones or to reinforce the remaining original timber elements

- Adding timber, steel or synthetic reinforcement to the outside of the repaired timber frame.

5. Aesthetic restoration

The aesthetic restoration is only necessary to restore the lost original shape of the damaged areas. The creation of a uniform surface is achieved by filling with putty or by localised wood filling. Colouring should be done in a lower tone than the original to differentiate it from the original surface. It is recommended to use paints with a high reversibility index, which differ in composition from the original and have very good chemical and colour stability during ageing.

5.1. Finishing

Finally, a synthetic polish is recommended as a protective resin or, if accurately diagnosed, similar to the original varnish.

Preventive consolidation of wooden parts of “ELENI P.”

The salvage interventions that were implemented focused on strengthening the surface and structure of the wooden parts that needed to be saved. These procedures were carried out in parallel with controlled dismantling wherever and whenever necessary. Finally, all parts were transferred to a safe location in compliance with strict safety standards and with preventive conservation in mind.